Do larger labels affect printing quality?

Not necessarily! The size of a label doesn’t inherently affect printing quality, but there are factors to consider when printing larger labels to ensure optimal results:

Factors That Impact Printing Quality for Larger Labels

- Resolution of the Design

- Larger labels require high-resolution artwork to maintain sharpness and clarity. A design with low resolution may appear pixelated or blurry when scaled up.

- Use vector files (like AI, SVG, or PDF) or high-quality images (300 DPI or higher) for best results.

- Printing Method

- Digital Printing: Excellent for large labels with intricate designs and gradients.

- Offset Printing: Provides superior quality for large quantities but requires proper plate setup.

- Flexographic Printing: Great for large labels on flexible materials like packaging or vinyl.

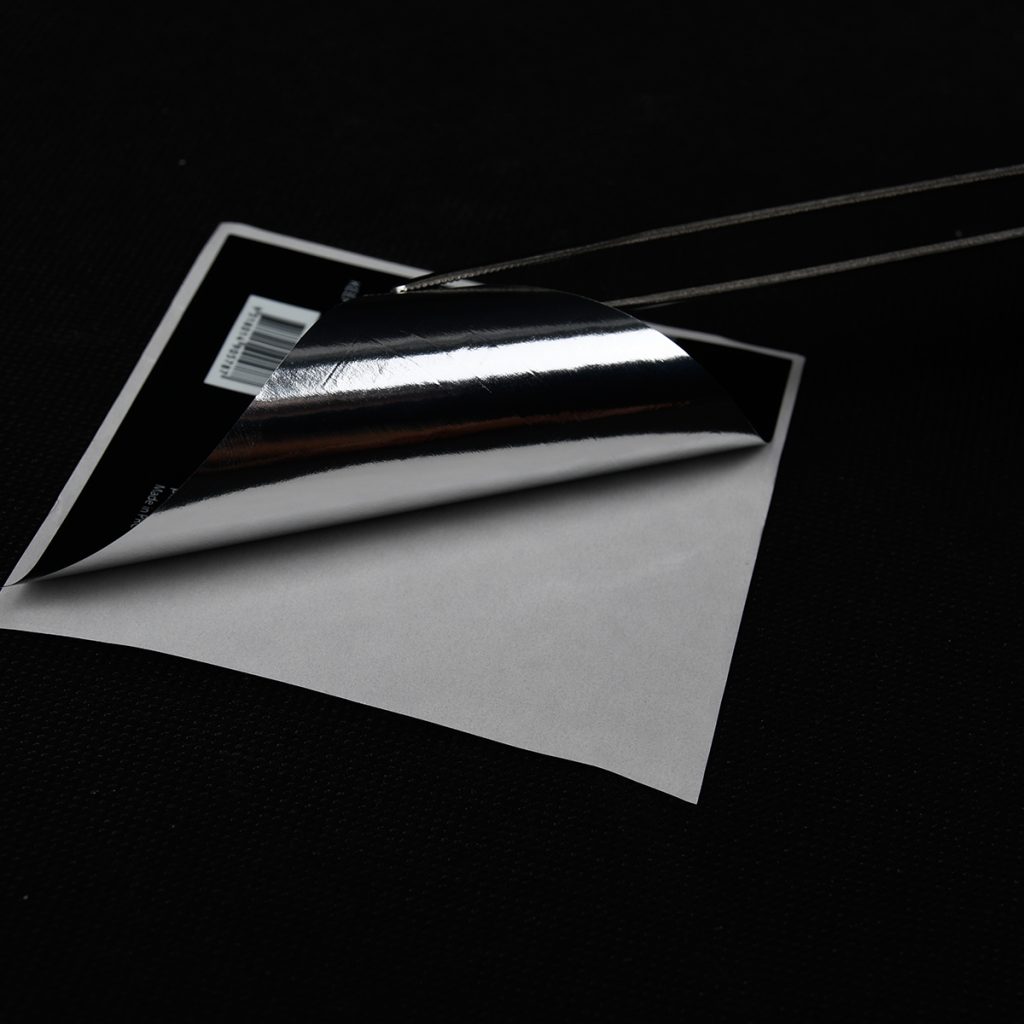

- Material Choice

- For larger labels, ensure the material is durable and doesn’t warp or wrinkle during application.

- Vinyl or laminated paper works well for oversized labels, as they offer stability and prevent damage.

- Ink Consistency

- Larger labels require uniform ink application. Poor-quality printers might result in uneven coloring, streaks, or blotches.

- Advanced machines (like those at MOJ Printing Factory!) ensure consistent, vibrant results, even on large-scale designs.

- Cutting and Alignment

- For larger labels with unique shapes, die-cut precision is key. Misalignment can ruin the aesthetic.

- Application Surface

- A smooth and clean surface ensures that large labels stick evenly without bubbles or creases.